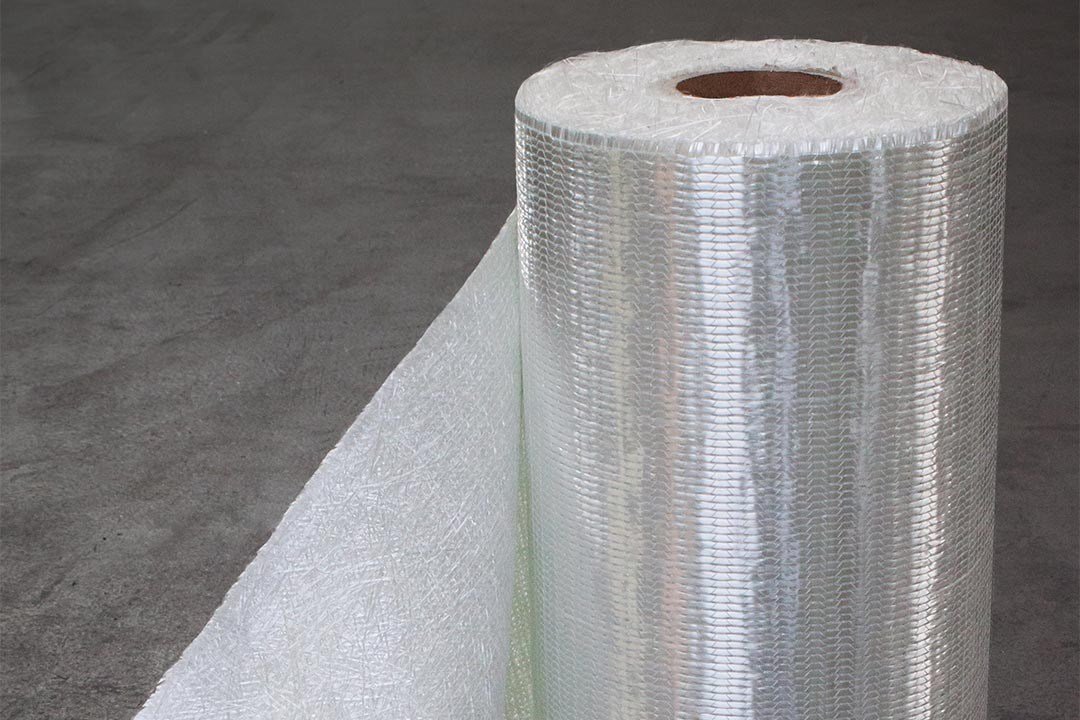

Glasfasermatten für das

RS MaxPatch® System

Grabenloses Reparaturverfahren mit DIBt-Zulassung

Zusammen mit den Schlauchlining-Sanierungssystemen steht RS MaxPatch® für schnelle, grabenlose und punktuelle Reparaturen zur Verfügung.

RS MaxPatch® ist ein bewährtes, vor Ort aushärtendes Kurzlinersystem zur Erneuerung kurzer Abschnitte in drucklosen Rohren von DN 100 bis DN 800.

Das korrosionsbeständige (E-CR-Glas) Glasfaser-Composite-System eignet sich hervorragend zur Reparatur und Versiegelung von Rohrschäden.

Anwendungsbeispiele:

- Kleine Risse

- Lecks

- Abzweigungsundichtigkeiten

- Korrosionsschäden

- Wurzeleinwuchs

Die hochfeste Harz-/Glasfasermatrix bietet eine enorme Strukturfestigkeit bei extrem schlankem Profil, was den Rohrdurchfluss nicht behindert, sondern verbessert.

Aushärtung auch unter Wasser

RS MaxPatch® härtet bei Umgebungstemperaturen praktisch ohne Schrumpfung und sogar unter Wasser aus. Das Harz sorgt für die bestmögliche Abdichtung des defekten Rohres und macht den Einsatz eines Preliners und eines Heizsystems überflüssig.

RS MaxPatch® verfügt über umfangreiche Eignungsprüfungen und ist durch das Deutsche Institut für Bautechnik (DIBt) als Verfahren zugelassen.

Haben Sie Fragen?

Möchten Sie mehr erfahren, haben Sie eine spezielle Frage zum RS MaxPatch® System oder wünschzen Sie eine Bestellung? Wir helfen Ihnen gerne direkt weiter.

Markus Dinklage

Vertriebsleiter DE

Jürgen Haug

Vertriebsleiter AT

Christoph Turk

Niederlassungsleiter

Franziska Rosser

Prokuristin

Technische Daten

Durchmesserbereich

• DN 100 – DN 800

Technische Daten

• RS MaxPatch Advantex-ECR-Glas

• Glasmatten Rollen in 330 mm/ 415 mm/ 510 mm und 1300 mm Breite

• Gewichte: 1086 g/m² oder 1387 g/m²

Qualitätssicherung

• RAL-Gütezeichen S27.10 (Wasser) & S27.2 (Dampf)

• DIBt – Zulassung Z-42.3 – 389

• DIBt – Zulassung Z-42.3 – 454

• DIBt – Zulassung Z-42.3 – 487 [innerhalb von Gebäuden]

Produktinformationen als PDF Download

Geräte

Verbrauchsstoffe

Ausbauvarianten

Anwendung

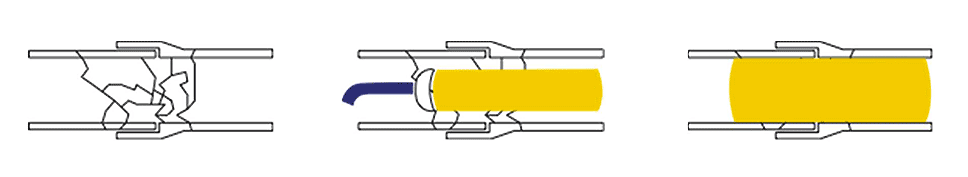

Zum Schutz des Packers wird zuerst ein Trennmittel auf den Packer aufgetragen. Danach wird der Packer mit einer Schutzfolie gleichmäßig umwickelt und fixiert.

Die Größe der Glasfasermatte wird berechnet. Sie ist abhängig von der Schadstelle und einer vorgeschriebenen Überlappung.

Die verschiedenen Harz-Komponenten werden gemäß der Verfahrensbeschreibung gemischt. Danach wird das Harz mehrfach auf der Glasfasermatte verteilt.

Die imprägnierte Glasfasermatte wird auf den vorbereiteten Packer mehrfach aufgewickelt, fixiert und anschließend in das Rohr eingeschoben.

Der Packer wird an der Schadstelle positioniert. Die Aushärtung erfolgt unter dem vorgegebenen Druck in der errechneten Aushärtungszeit.