RS MaxLiner® 12t

Unser Multitalent für Sanierungsprofis

Das System RS MaxLiner® ist ein seit vielen Jahren etabliertes System zur Sanierung und Renovation von Haus- und Grundleitungen. Ob Hausanschluss oder Inhouse-Sanierung: Die Stärke des Systems liegt darin, dass es für verschiedene Anwendungen geeignet ist und ein breites Spektrum an Nennweiten abbildet (DN 50 bis DN 400). Wir verwenden eigens dafür entwickelte Epoxidharze, mit denen Sie in Bezug auf Temperaturbeständigkeit, Handhabbarkeit und Aushärtung flexibel bleiben. Zu den typischen Anwendungen des RS MaxLiners® gehören

- Grundleitungen

- Leitungen innerhalb von Gebäuden

- Fallstränge

- Anschlussleitungen in Industrie- und Gewerbebetrieben

Der RS MaxLiner® zeichnet sich durch seine Material- und Technikvielfalt aus, die es ermöglicht für jeden Anwendungsfall eine maßgeschneiderte Lösung auszuwählen.

Die Vorteile liegen auf der Hand:

- Bogengängigkeit

- Sanierung von bis zu vier Dimensionswechseln

- Sanierungen mit offenem Ende

- Sanierungen bei erschwerter Zugänglichkeit

Für ausführende Unternehmen:

Wir rüsten Sie aus!

Wir bieten Ihnen das komplette RS MaxLiner® System für die Sanierung von Haus- und Grundleitungen in einem voll ausgebauten Fahrzeug an, inklusive

MaxPox®: Wirksamer Schutz vor Korrosion und Wurzeleinwuchs

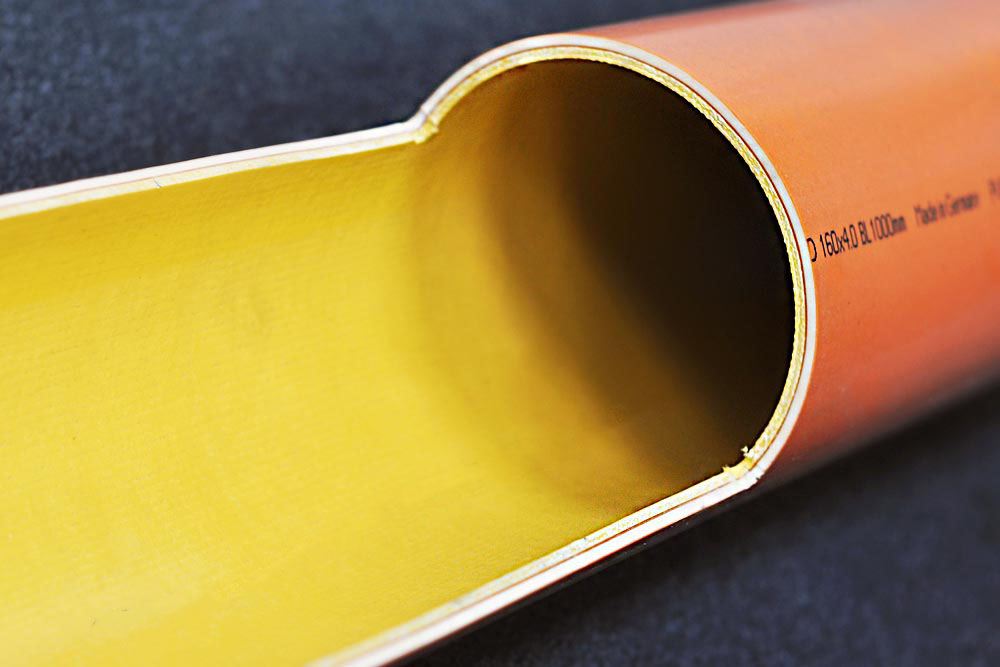

Und wie lange hält ein mit den MaxLiner® saniertes Rohr? Auf diese Frage haben wir eine Antwort: Da das Epoxidharz-System MaxPox® und der Liner an der Rohrinnenwand ein neues Rohr bilden, besteht eine luftdichte, nahtlose Verbindung. Auf diese Weise kann weder Feuchtigkeit entstehen noch Wasser eindringen – Betonfraß und Korrosion werden gestoppt. Dank des Epoxidharzes MaxPox® bleibt das mit dem System RS MaxLiner® sanierte Rohr außerdem frei von Wurzeleinwuchs. Dies wurde durch das Institut für Pflanzenbiologie Basel in Labor- und Feldversuchen nachgewiesen.

RS LinerGun®

Die RS LinerGun® ist ein leichtes Inversionsgerät, das bei der Sanierung von Rohren mit Inversionstechnik flexibel einsetzbar ist. Beliebt ist das Gerät vor allem wegen der einfachen Handhabung. Die RS LinerGun® eignet sich sowohl für offene als auch für geschlossene Sanierungen.

RS CCM®

Die RS CCM® ist eine vollautomatische Dosier- und Mischanlage, die die luftfreie Mischung der Harzkomponenten ermöglicht und gleichzeitig die Verarbeitungszeit optimiert. Weiterer Vorteil der RS CCM®: Der komplette Einbauablauf wird dokumentiert und kann bei Bedarf an den Auftraggeber weitergegeben werden.

Haben Sie Fragen?

Möchten Sie mehr erfahren, haben Sie eine spezielle Frage zum RS MaxLiner® System oder möchten Sie eine Bestellung aufgeben? Wir helfen Ihnen gerne direkt weiter.

Markus Dinklage

Vertriebsleiter DE

Jürgen Haug

Vertriebsleiter AT

Christoph Turk

Verkauf / Technischer Leiter

Franziska Rosser

Prokuristin

Technische Daten

Mögliche Anwendungsbereiche des RS MaxLiner®

• Haus- und unterirdische Leitungen aller Art vom Keller bis zum Abwassersystem

• Rohre werden vertikal vom Dach bis in den Keller saniert

• Dränagerohre für Garage, Garten und Vorplatz

• Längen von bis zu 100 m mit Bögen bis 90° möglich

• Alle Arten von Host-Pipe-Materialien

• Selektive Sanierung von Buchsen und Löchern

• Installation durch vorhandene Kanäle und Öffnungen

Durchmesserbereich

• DN 70 mm bis DN 400 mm

Technische Daten

• Harzmischanlage Leistung: 18 kg/min

• Vakkuumpumpe Saugvermögen: 16 m³/h

• Tanks Fassvermögen: Harz 480 l, Härter 160 l

• Stromaggregat Leistung: 5kW

Ausbaubeispiele für die individuelle Zusammenstellung des RS Maxliner® 12t

• Mischanlage RS CCM® inkl. SPS Steuerung über Siemens Touch Panel

• Inklusive Fernwartung

• Externe Vakuumpumpe V-VTN16 (Saugvermögen: 16 m³/h)

• Standard Mischkopf zu CCM

• Klimasystem für Harz und Härter

• Gemäß Maschinenrichtlinien konforme Tanks – Harz 480 l, Härter 160 l

• Externe Befüllvorrichtung, Stromaggregat 5 kW

• Jeweils eine Exzenterschneckenpumpe für Epoxidharz/Härter

• Inkl. RS Kalibirerwalzentisch DN 300 / DN 400, elektrisch mit Trommelmotoren und eingebautem Untergestell

Weitere Ausrüstung für den RS MaxLiner® 12t

• RS LinerGun® Inversionsgerät oder RS LinerCannon® Inversionstrommel

• Mobile Heizeinheit wie RS HotBox® oder Steam Unit

• Fräsroboter RS-Cutter®

Qualitätssicherung

• RAL-Gütezeichen S27.10 (Wasser) & S27.2 (Dampf)

• DIBt – Zulassung Z-42.3 – 389

• DIBt – Zulassung Z-42.3 – 454

• DIBt – Zulassung Z-42.3 – 487 [innerhalb von Gebäuden]

Produktinformationen als PDF Download

Geräte

Verbrauchsstoffe

Ausbauvarianten

Installation

Der RS MaxLiner® wird je nach Leitungsführung vom Schacht, von der Kelleröffnung oder von Dachabläufen eingebaut. Für die verschiedenen Leitungssysteme stehen spezielle Linertypen sowie Epoxidharze und -härter zur Verfügung.

Der Liner wird auf die benötigte Länge zugeschnitten und die beiden Komponenten (MaxPox® Harz und Härter) werden gemischt.

Mit der RS LinerGun® (Inversionsgerät) wird der getränkte Liner mit Druckluft im beschädigten Rohr installiert. Der Liner wird bis zur Aushärtung der Epoxidmischung unter Druckluft gehalten. Heißes Wasser oder Dampf kann die Aushärtung beschleunigen.

Die Epoxidmischung wird in den Liner eingefüllt und mit der Kalibrierwalze im Liner gleichmäßig verteilt.

Durch den Liner verschlossene Einläufe können mit dem Fräsroboter RS Cutter geöffnet werden.